Design Elements

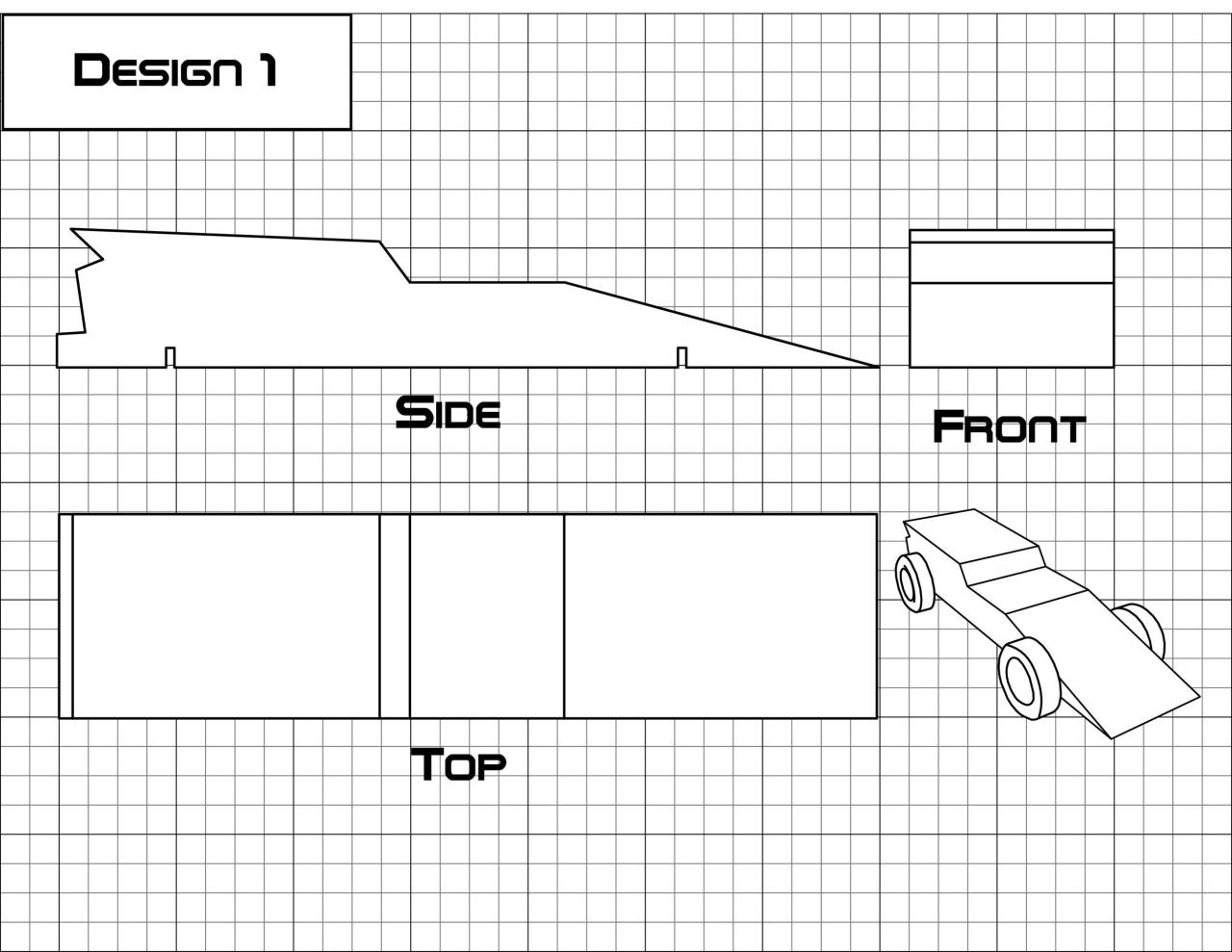

Pinewood derby car templates – Creating a successful pinewood derby car template requires careful consideration of various design elements. These elements influence the car’s speed, stability, and overall performance.

The optimal dimensions for a pinewood derby car are governed by the official race rules, typically specifying a length of around 7 inches and a width of 2.5 inches. Weight distribution is crucial, with the ideal center of gravity positioned slightly behind the front axle.

This ensures stability and prevents the car from flipping over during the race.

Aerodynamic Features

Aerodynamic features play a significant role in reducing drag and increasing speed. Streamlining the car’s shape, reducing frontal area, and minimizing sharp edges can enhance its aerodynamic efficiency.

Wheel Selection

The choice of wheels affects the car’s speed and stability. Wider wheels provide greater stability, while narrower wheels reduce rolling resistance. Selecting wheels with low friction bearings minimizes energy loss due to friction.

Axle Alignment

Proper axle alignment is essential for smooth and efficient movement. Axles should be parallel and perpendicular to the car’s body, ensuring the wheels roll smoothly without wobbling or causing friction.

Friction Reduction Techniques

Reducing friction is crucial for maximizing speed. Using graphite or other lubricants on the axles and wheels can significantly decrease friction. Additionally, polishing the wheels and axles can further reduce resistance.

Material Selection and Preparation

Choosing the right wood for your pinewood derby car is essential for both speed and durability. Here’s a guide to help you make the best selection and prepare your wood properly.

Wood Types

The most common types of wood used for pinewood derby cars are pine, basswood, and balsa wood. Each has its own advantages and disadvantages:

- Pine:Soft and easy to work with, but not as strong as other woods.

- Basswood:Harder than pine, but still relatively easy to shape. Provides a good balance of strength and weight.

- Balsa wood:Very lightweight and easy to cut, but also very fragile. Requires careful handling and reinforcement.

Wood Preparation

Once you’ve selected your wood, it’s important to prepare it properly for construction:

- Cutting:Use a sharp saw to cut the wood to the desired shape. Make sure to cut cleanly and avoid splintering.

- Sanding:Sand the wood smooth to remove any rough edges or burrs. This will help reduce drag and improve aerodynamics.

- Shaping:If desired, you can use a file or sandpaper to shape the wood into a more aerodynamic form. This can help increase speed.

Proper material selection and preparation are crucial for building a fast and durable pinewood derby car. By following these guidelines, you can give your car the best chance of success on race day.

Templates and Customization: Pinewood Derby Car Templates

Pinewood derby car templates offer a great starting point for creating a winning design. These templates are available in various skill levels and design complexities, making them suitable for both beginners and experienced builders.

Customizing these templates is easy and allows you to create a unique and personalized car. You can adjust the dimensions, modify the shape, or add your own design elements to make your car stand out.

Computer-Aided Design (CAD) Software

For precise template creation and customization, consider using computer-aided design (CAD) software. CAD software provides advanced tools for designing and modifying templates, ensuring accuracy and consistency in your measurements.

Assembly and Finishing

Assembling and finishing a pinewood derby car is a crucial step in the process. It requires careful attention to detail, proper techniques, and a keen eye for precision. This guide will provide a step-by-step approach to assembling your car, highlighting the importance of gluing, alignment, and securing components.

Additionally, it will discuss finishing techniques, including painting, sealing, and applying decals, to enhance the car’s appearance and performance.

Gluing

Gluing is a fundamental aspect of assembling a pinewood derby car. Choose a high-quality wood glue specifically designed for wood. Apply the glue sparingly to the surfaces to be joined, and ensure they are properly aligned before pressing them together.

Use clamps or weights to hold the components firmly in place while the glue dries. Allow sufficient time for the glue to dry completely before moving on to the next step.

Alignment, Pinewood derby car templates

Proper alignment is essential for a well-performing pinewood derby car. Use a ruler or measuring tape to ensure that the wheels are parallel and equidistant from the center of the car. Check the alignment from different angles to identify any discrepancies.

Adjust the components as needed until the car rolls smoothly and straight on a flat surface.

Securing Components

Once the components are aligned, it is important to secure them firmly. In addition to gluing, you can use small nails or screws to reinforce the joints. Countersink the nails or screws slightly below the surface of the wood to avoid creating obstacles that could affect the car’s performance.

Test the car on a track or incline to ensure that it stays together and performs as intended.

Painting and Finishing

Painting and finishing not only enhance the appearance of your pinewood derby car but also improve its performance. Choose a paint that is specifically designed for wood and apply it in thin, even coats. Allow each coat to dry completely before applying the next.

You can also use sandpaper to smooth the surface of the car and remove any imperfections.

Sealing

Sealing the car’s surface helps protect it from moisture and wear. Apply a clear sealant or varnish over the paint to create a durable finish. Allow the sealant to dry completely before handling the car.

Applying Decals

Decals can add a personal touch to your pinewood derby car. Choose decals that are designed for wood or plastic surfaces and apply them according to the manufacturer’s instructions. Use a ruler or measuring tape to ensure that the decals are evenly spaced and aligned.

Popular Questions

What are the key design elements for a successful pinewood derby car?

Optimal dimensions, weight distribution, aerodynamic features, wheel selection, axle alignment, and friction reduction are all crucial considerations.

How do I choose the right wood for my pinewood derby car?

Consider the density, grain pattern, and weight of different wood types. Popular choices include pine, basswood, and balsa wood.

Can I customize pinewood derby car templates?

Yes, you can modify and personalize templates using hand tools or computer-aided design (CAD) software.

What are the steps involved in assembling a pinewood derby car?

Follow a step-by-step guide to glue, align, and secure the various components, ensuring proper weight distribution and alignment.

How can I enhance the appearance and performance of my pinewood derby car?

Apply paint, sealant, and decals to improve aesthetics and reduce friction. Consider adding weights or streamlining the design for optimal performance.