Drill Bit Specifications

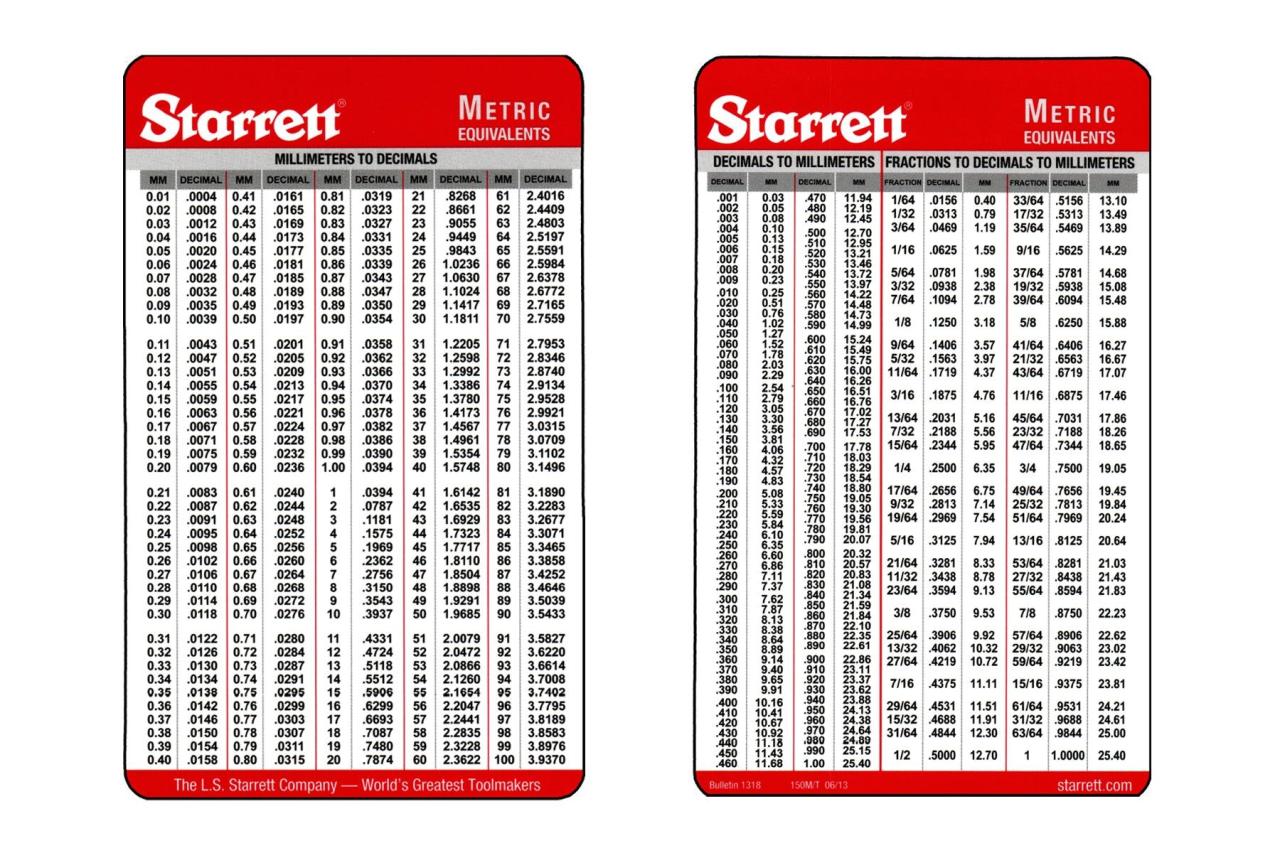

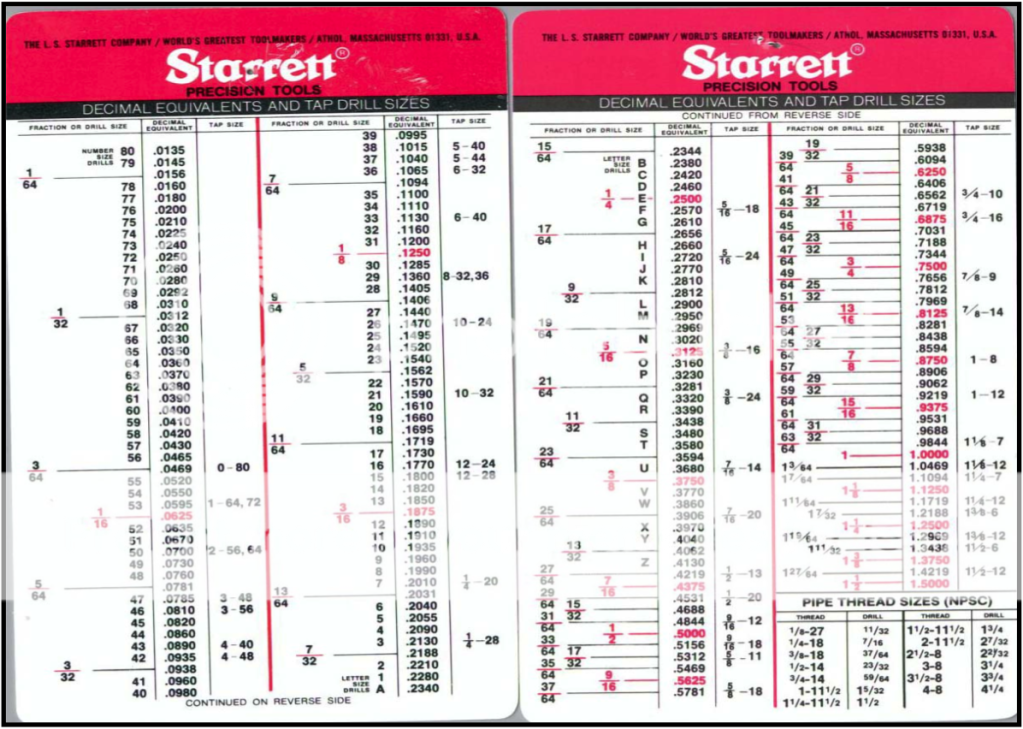

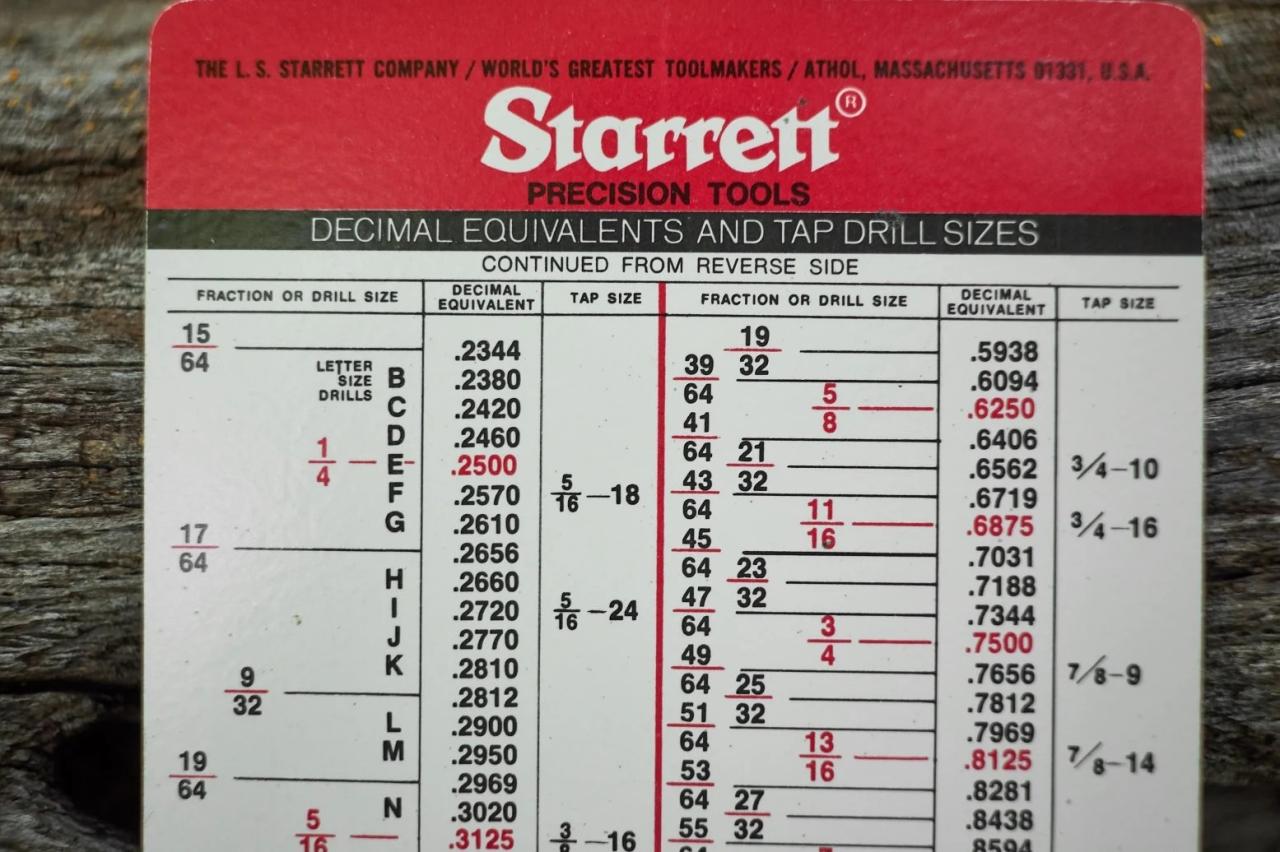

Starrett drill tap chart – Drill bits are cutting tools used to create holes in various materials. They come in a wide range of specifications to suit different applications.

The primary specifications of drill bits include size, material, and coating.

Size, Starrett drill tap chart

Drill bit sizes are typically measured in inches or millimeters. The diameter of the hole created by the drill bit is determined by the size of the drill bit.

Material

Drill bits can be made from various materials, including:

- High-speed steel (HSS)

- Carbide

- Cobalt

The choice of material depends on the material being drilled and the desired performance.

Coating

Drill bits can be coated with various materials, such as:

- Titanium nitride (TiN)

- Titanium carbide (TiC)

- Diamond

Coatings can improve the performance and durability of drill bits.

| Specification | Applications |

|---|---|

| Small diameter (less than 1/4 inch) | Drilling small holes in wood, plastic, and thin metal |

| Medium diameter (1/4 inch to 1/2 inch) | Drilling holes in wood, metal, and concrete |

| Large diameter (greater than 1/2 inch) | Drilling large holes in thick metal and concrete |

| High-speed steel (HSS) | General-purpose drilling in most materials |

| Carbide | Drilling hard materials such as metal and concrete |

| Cobalt | Drilling high-temperature alloys |

| Titanium nitride (TiN) | Improving wear resistance and cutting speed |

| Titanium carbide (TiC) | Increasing hardness and durability |

| Diamond | Drilling very hard materials such as glass and ceramics |

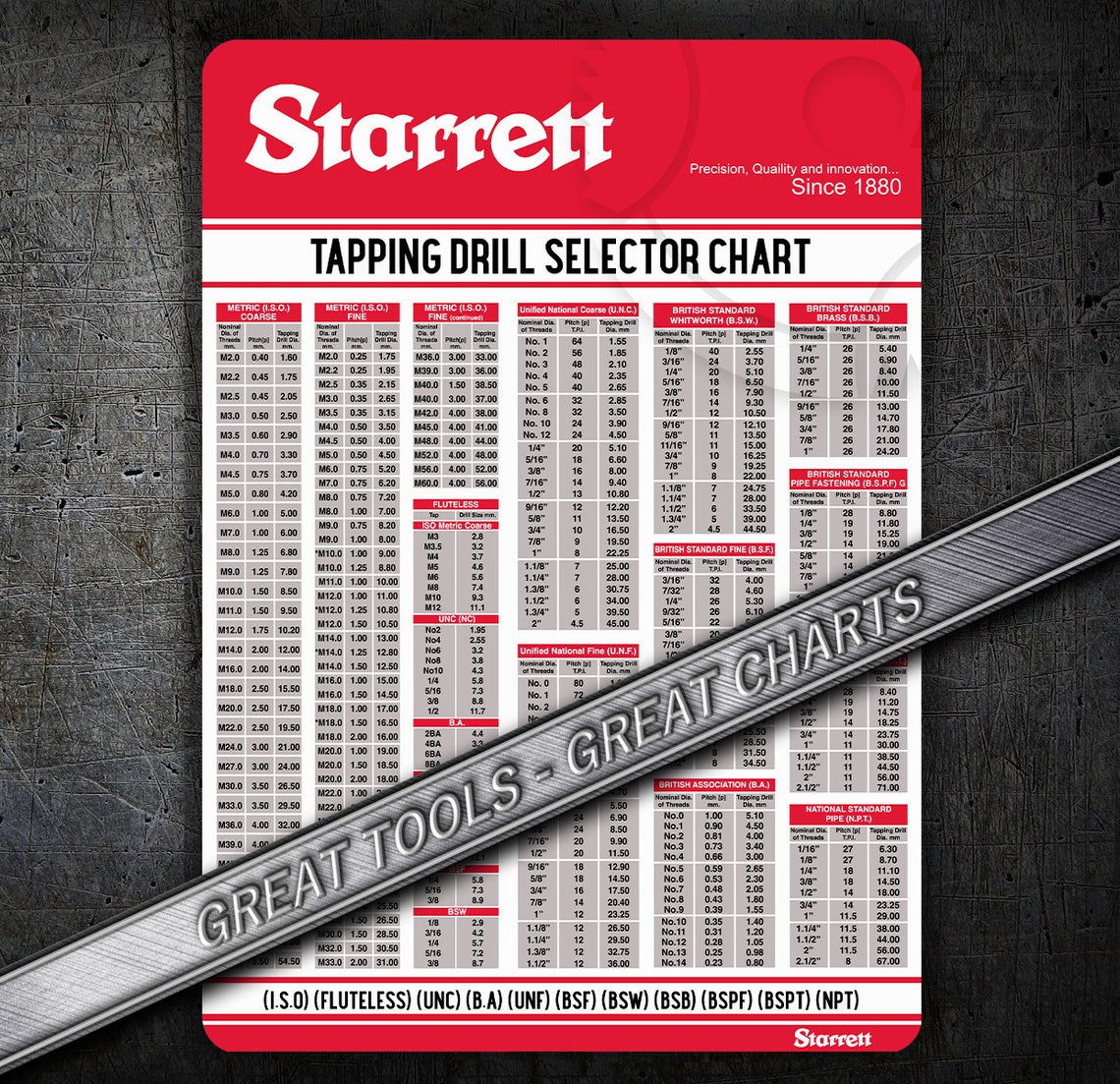

Tap Size and Thread Standards

Taps come in various sizes and thread standards to accommodate different hole sizes and thread types. Understanding these standards is crucial for selecting the correct tap for the job.

Common Tap Sizes and Thread Standards

The table below compares the most common tap sizes and thread standards used in the industry:

| Tap Size | Thread Standard | Description |

|---|---|---|

| #0 to #12 | Numbered (UNC/UNF) | Used for small holes, such as in electronics and jewelry |

| 1/16″ to 1″ | Fractional (UNC/UNF) | Commonly used in general engineering and construction |

| M1 to M52 | Metric (ISO) | International standard used in automotive, aerospace, and other industries |

Using a Starrett Drill Tap Chart

Starrett drill tap charts are an essential tool for machinists and hobbyists alike. They provide a quick and easy way to determine the correct drill bit size for a given tap size. Using a Starrett drill tap chart is simple, and can be done in just a few steps.

To use a Starrett drill tap chart, first locate the tap size you are using in the “Tap Size” column. Once you have found the tap size, look across the row to the “Drill Bit Size” column. The number in this column is the correct drill bit size to use for the tap size you have selected.

For example, if you are using a 1/4-20 tap, the correct drill bit size to use is 13/64″.

Starrett drill tap charts are also useful for determining the correct tap size to use for a given hole size. To do this, simply find the hole size in the “Hole Size” column and look across the row to the “Tap Size” column.

The number in this column is the correct tap size to use for the hole size you have selected.

For example, if you have a 13/64″ hole, the correct tap size to use is 1/4-20.

Starrett drill tap charts are a valuable tool for anyone who works with taps and dies. They are easy to use and can save you a lot of time and frustration.

Applications of Drill Tap Charts: Starrett Drill Tap Chart

Drill tap charts are widely utilized in various industries to ensure precision and accuracy in drilling and tapping operations. Their applications extend beyond manufacturing and construction, reaching into diverse fields.

In manufacturing, drill tap charts serve as indispensable tools for selecting the appropriate drill bit size for creating holes that will accommodate specific taps. This ensures that tapped threads conform to industry standards and meet the required specifications.

Construction

Within the construction industry, drill tap charts are crucial for ensuring the proper installation of electrical and plumbing fixtures. By referencing the chart, contractors can determine the correct drill bit size for creating holes that will accommodate electrical boxes, conduit, and plumbing pipes.

Automotive

In the automotive sector, drill tap charts play a vital role in the maintenance and repair of vehicles. Technicians rely on these charts to select the correct drill bit size for tapping holes in engine blocks, cylinder heads, and other components, ensuring secure and leak-free connections.

Aerospace

The aerospace industry demands the highest levels of precision and accuracy. Drill tap charts are used to determine the optimal drill bit size for creating holes in aircraft components, ensuring that they meet stringent specifications and maintain structural integrity.

FAQ Overview

What are the key specifications to consider when selecting a drill bit?

Size, material, and coating are the primary factors to evaluate when choosing a drill bit. The size determines the diameter of the hole you want to drill, while the material and coating influence the bit’s durability and performance.

How do I determine the correct tap size for a given application?

Refer to the Starrett drill tap chart to find the recommended tap size based on the desired hole size and thread type. The chart provides a comprehensive list of common drill bit and tap size combinations.

What are the different types of thread standards used in tapping?

There are various thread standards, such as Unified National Coarse (UNC), Unified National Fine (UNF), and Metric (M). Each standard has its own specifications for thread pitch and diameter.

2 comments

Comments are closed.